Understanding the Industrial Wood Chip Burner System: Key Benefits and Specifications

Understanding the Industrial Wood Chip Burner System: Key Benefits and Specifications

Blog Article

In today's eco-conscious industrial landscape, efficient and sustainable heating solutions are more crucial than ever. The industrial wood chip burner system stands out as an innovative biomass heating solution, harnessing the power of wood chips to generate heat for various industrial applications. Below, we explore the key benefits of this system, its technical specifications, and how it operates.

Key Benefits of the Wood Chip Burner System

1. Renewable and Cost-Effective Heat Generation

The wood chip burner system offers a renewable method for generating heat, utilizing wood chips—often a byproduct of forestry or sawmill operations. This approach not only reduces reliance on traditional fossil fuels but also potentially lowers operational costs. By switching to biomass, companies can benefit from a more sustainable and economically viable energy source, contributing to a smaller carbon footprint.

2. Real-Time Monitoring for Optimal Drying

One of the standout features of this burner system is its ability to monitor wood chip moisture content in real-time. Integrated humidity sensors provide operators with precise data, allowing for adjustments to the burner temperature based on the specific moisture levels of the drying material. This capability enhances drying efficiency and ensures consistent quality in the final product, significantly improving overall processing efficiency.

3. Utilization of Waste Materials

The burner system effectively minimizes waste by using wood chips and sawdust—materials that would otherwise contribute to landfill issues. By converting these waste products into a valuable energy source, industries can play a pivotal role in promoting sustainability and reducing environmental impact.

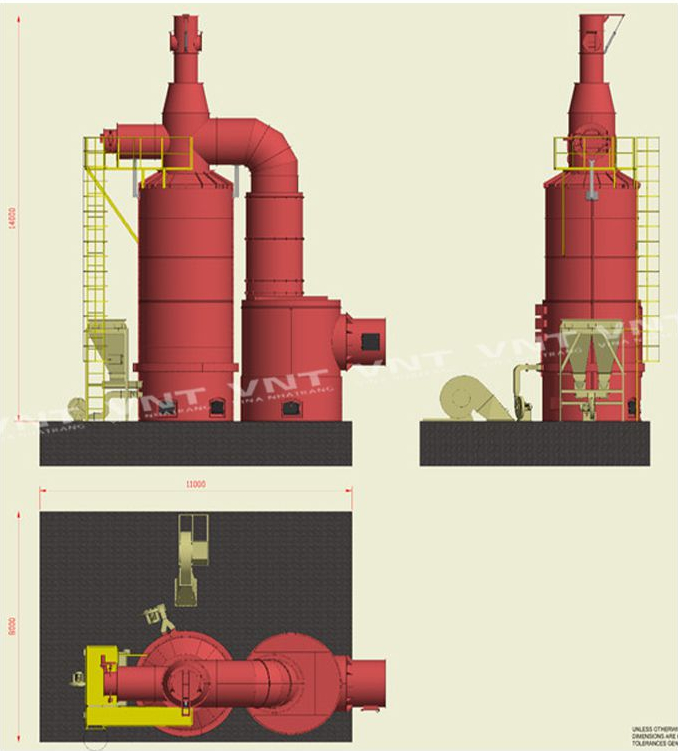

What is the Burner System?

The industrial wood chip burner system is designed to be highly efficient and fully automated. It can handle various qualities of wood chips, including recycled and waste materials. Key functionalities include automatic ignition, fuel feeding, and shutoff, making it an ideal choice for industrial applications requiring consistent and reliable heat generation.

Technical Specifications

Heat Capacity: 6,000 – 10,000 kW

Burner Type: Fluid bed grate

Combustion Material: Wood chips (dimensions: 30×30 mm, thickness: 5 – 10 mm)

Moisture of Combustion Material: < 40%

Burner Control: Automatic with PLC screen

Control and Display Functions:

Control fan speed according to drying temperature

Adjust combustion material supply

Periodic slag collection

Fresh air intake regulation

Automatic smoke release in case of problems

Principle of Operation

The burner system operates by feeding combustion material into the combustion chamber via a screw conveyor. A blower below the fluidized bed creates stable combustion by evenly distributing air. This system allows for optimal airflow and temperature control, mixing hot industrial wood chip burner air from the combustion chamber with fresh outdoor air to meet the drying capacity requirements. If any issues are detected, the exhaust valve automatically opens to release smoke, ensuring safety and efficiency.

Advantages of the Wood Chip Burner System

Automatic Temperature Control: Maintains optimal drying conditions.

Reduced Drying Time: Enhances productivity and efficiency.

Modern Technology: Incorporates advanced features for seamless operation.

High Durability: Built to withstand demanding industrial environments.

User-Friendly: Simple operation reduces the need for extensive training.

Energy Efficient: Lowers electricity consumption.

Labor Efficiency: Minimizes workforce requirements, reducing operational costs.

Conclusion

The industrial wood chip burner system presents a forward-thinking solution for companies looking to integrate sustainable practices into their operations. By providing a renewable and cost-effective method of heat generation, facilitating real-time monitoring for optimal drying, and utilizing waste materials, this system not only enhances operational efficiency but also supports environmental stewardship. As industries increasingly prioritize sustainability, investing in a wood chip burner system can lead to significant long-term benefits.